Yamaha 75hp crankshaft Bearings

$110.00

Yamaha 75hp crankshaft Bearings online

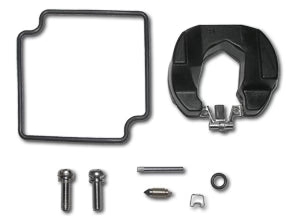

Yamaha 75hp crankshaft Bearings are essential components that facilitate the smooth rotation of the crankshaft, ensuring efficient engine performance. These bearings support the crankshaft’s rotational movement, minimizing friction and wear, which is crucial for the engine’s longevity and reliability. Buy Yamaha 75hp crankshaft Bearings.

Understanding Yamaha 75hp Crankshaft Bearings

Yamaha 75hp Crankshaft bearings are designed to support the crankshaft within the engine block, allowing it to rotate freely. They are typically made from high-strength materials such as steel or bronze and are precision-engineered to withstand the immense forces generated during engine operation. In the Yamaha 75hp outboard motor, these bearings are specifically designed to handle the unique stresses and operating conditions of marine environments. Yamaha 75hp crankshaft Bearings for sale.

Types of Yamaha 75hp Crankshaft Bearings

The Yamaha 75hp outboard motor utilizes several types of crankshaft bearings, each serving a specific function:

•Top Bearing: Located at the upper end of the crankshaft, the top bearing supports the crankshaft’s rotation and is crucial for maintaining proper alignment. A common part number for this bearing is 93310-636U4.

•Bottom Bearing: Situated at the lower end, the bottom bearing supports the crankshaft against the engine block, ensuring stability and reducing vibration. An example part number for this bearing is 93306-206U5.

•Thrust Bearing: This bearing absorbs axial loads, preventing the crankshaft from moving forward or backward within the engine. A typical part number for the thrust bearing is 93310-835U8.

Common Issues with Yamaha 75hp Crankshaft Bearings.

Over time, crankshaft bearings can experience wear and tear due to continuous operation. Common issues include:

•Wear and Tear: Continuous operation can lead to the degradation of bearing surfaces, resulting in increased friction and potential engine damage.

•Corrosion: Exposure to saltwater can cause corrosion, compromising the bearing’s integrity and leading to premature failure.

•Contamination: Debris or contaminants in the engine oil can damage bearing surfaces, affecting performance.

Symptoms of Bearing Issues

Identifying bearing issues early can prevent extensive engine damage. Symptoms may include:

•Unusual Noises: Grinding or knocking sounds during operation may indicate bearing problems.

•Vibration: Excessive vibration can be a sign of bearing wear or misalignment.

•Loss of Power: Decreased engine performance or power loss may result from bearing issues.

Maintenance and Replacement

Regular maintenance is crucial to prolong the life of crankshaft bearings:

•Routine Inspections: Regularly check for signs of wear, corrosion, or contamination.

•Oil Changes: Use high-quality, marine-grade oil and change it at recommended intervals to ensure proper lubrication.

•Professional Servicing: If bearing issues are suspected, consult a certified marine mechanic for diagnosis and replacement.

Advantages of Yamaha 75HP Crankshaft Bearings

1. Smooth Engine Operation: Crankshaft bearings allow the crankshaft to spin with minimal friction, ensuring smooth and efficient power delivery.

2. Durability Under Load: Designed to handle high RPM and constant load, they support the crankshaft under stress, especially during rapid throttle changes and heavy use.

3. Corrosion Resistance: Yamaha uses marine-grade, corrosion-resistant materials, essential for longevity in saltwater and freshwater environments.

4. Heat Dissipation: Bearings help dissipate heat generated by engine operation, preventing overheating and reducing wear.

5. Vibration Reduction: Properly functioning bearings reduce engine vibration, which improves overall ride comfort and reduces wear on other engine parts.

6. Longevity of Engine: Quality crankshaft bearings prolong engine life by preventing metal-on-metal contact, preserving the crankshaft and block integrity.

Frequently Asked Questions

How often should I replace the crankshaft bearings in my Yamaha 75hp outboard?

The replacement interval depends on usage and maintenance. Regular inspections can help determine when replacement is necessary.

Can I replace the crankshaft bearings myself?

Replacing crankshaft bearings requires specialized knowledge and tools. It’s recommended to have a certified marine mechanic perform the replacement.

What are the signs that my crankshaft bearings need replacement?

Signs include unusual engine noises, excessive vibration, and decreased performance.

Conclusion

Crankshaft bearings are vital for the smooth operation of the Yamaha 75hp outboard motor. Regular maintenance and timely replacement are essential to ensure engine longevity and performance. By understanding the function and care of these components, boat owners can maintain their outboard motors in optimal condition. Yamaha 75hp crankshaft Bearings near me.

Be the first to review “Yamaha 75hp crankshaft Bearings” Cancel reply

Related products

Maintenance Parts & Repair Kits

Maintenance Parts & Repair Kits

Maintenance Parts & Repair Kits

Maintenance Parts & Repair Kits

Maintenance Parts & Repair Kits

Maintenance Parts & Repair Kits

Reviews

There are no reviews yet.